Paptic® for Product Packaging

Replacing unneeded plastics

Sustainability

Performance

Brand Value

The Perfect solution for replacing plastics in dry products packaging

Paptic® for product packaging is a heat-sealable, fiber-based material offering a premium solution to pack and protect your product in a sustainable way.

Paptic® offers a drop-in solution to replace plastics in dry product packaging. Whether you are packing yourself or using preformed packages, Paptic® material offers an effective way to replace plastics. The soft, strong, and flexible material allows durable packaging of items with sharp edges, delicate surfaces, and unique shapes

The unique haptics and recognizable look of your packaging will help your brand stand out on crowded supermarket shelves and improve your product attractiveness.

Sustainability

Does not have to involve big investments

Renewable

The main raw material of Paptic® mailers is wood from sustainably managed forests.

Resource

Efficient

Paptic® runs on the same packing lines operating with films without any modifications. It is also lightweight and strong, offering the same performance with less resources.

Recyclable

Paptic® materials are easy to recycle together with packaging papers and cardboard.

Performance

Combining sustainability with excellent performance

Considering changing your packing line to a fiber-based solution? Perhaps you have tested some heatsealable papers and noticed they tear easily on your current operating line? Well, this is not the case with Paptic® material! Paptic® offers a drop-in solution for FFS lines currently operating with films with no modifications needed.

Wrinkles, tearing, ink vanishing when material cracks? This will not happen with Paptic®. The material is strong and soft while offering a smooth touch without any wrinkles. Your packages will look nice all the way through logistics and handling.

Paptic® is actually so strong that you might want to consider a lower grammage compared to your current solution!

Brand Value

Make others follow your example in sustainability

With Paptic® you strengthen your brand’s sustainable frontrunner image. The softness of the material makes the opening experience unique for your customer and improves the overall customer experience.

When a brand makes responsible choices, consumers see the brand as a modern and valuable company that respects nature. Consumers prefer brands with whom they share the same values. Packaging material really matters, it actually increases the merchandise value of the product in the eyes of the consumers.

It is time to start using more modern materials and lead the way towards more responsible packaging.

Want to Hear More?

Contact us to find out how your company could make the switch from plastics to more sustainable packaging!

fischertechnik replaces plastic

fischertechnik, one of the sustainability forerunners in the toy industry, has replaced single-use plastic in pouches of its bio-based construction set with wood fibre-based Paptic® material.

Success case: Footprint Tools adopts a renewable and recyclable Paptic® for their product packaging

Footprint Tools, a hand tool manufacturer from the UK, moved their first products from traditional plastic and cardboard packaging into packaging made of renewable and recyclable at-scale Paptic® material. Working alongside Criterion Packaging of Sheffield together with the Paptic team, a new type of pack for the DIY/tool industry has been launched. Footprint Tools is the first in the hardware market to use lightweight but strong Paptic® material for their product packaging.

Success case: t-Shirt Pouch – Case Cos

Hennes & Mauritz brand COS chooses Paptic® material for t-shirt pouches.

With Paptic®, Hennes & Mauritz brand COS finds the perfect balance between packaging functionality, feel, and sustainability in its newly designed t-shirt pack.

A Perfect Material for product packaging

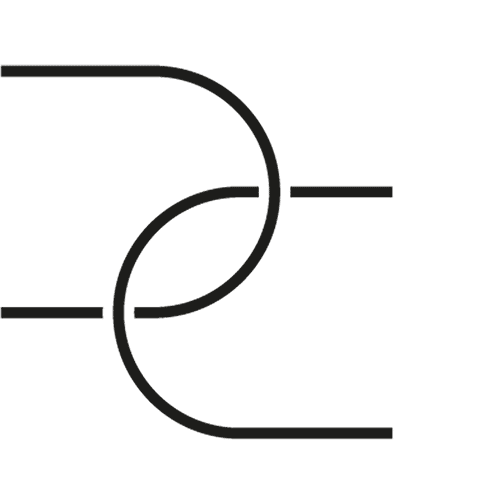

Paptic® materials can be converted on existing converting machines providing a flexible, scalable and sustainable solution for converters and their customers. The best Paptic® materials for product packaging are Paptic Apus® and Paptic Gavia®.

Paptic Perdix®

Paptic Perdix® is a sustainable heatsealable packaging material for product packaging. It is soft and silent with a silky feeling.

Barrier

Do you produce moist or fatty goods needing some extra protection?

We have a wide partner network converting our materials. Contact us to learn more.